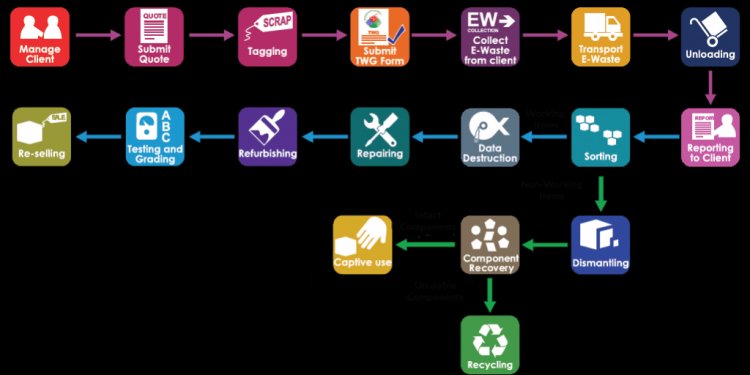

E Waste Disposal Process

E-waste refers to electronic waste. E-waste recycling is the reuse and reprocessing of electrical and electronic equipment of any type that has been discarded or regarded as obsolete. Some of the common E-wastes include: home appliances such as televisions, air conditioners, electric cookers and heaters, air condoners, fans, DVDs, Radios and microwaves among others; information technology equipments such as computers, mobile phones, laptops, batteries, circuit boards, hard disks, and monitors among others; and other electronic utilities such as leisure, lighting, and sporting equipments. Recycling of e-waste is a growing trend and was initiated to protect human and environmental health mainly due to the widespread environmental pollution impacts of e-waste.

E-waste refers to electronic waste. E-waste recycling is the reuse and reprocessing of electrical and electronic equipment of any type that has been discarded or regarded as obsolete. Some of the common E-wastes include: home appliances such as televisions, air conditioners, electric cookers and heaters, air condoners, fans, DVDs, Radios and microwaves among others; information technology equipments such as computers, mobile phones, laptops, batteries, circuit boards, hard disks, and monitors among others; and other electronic utilities such as leisure, lighting, and sporting equipments. Recycling of e-waste is a growing trend and was initiated to protect human and environmental health mainly due to the widespread environmental pollution impacts of e-waste.

According to Wikipedia,

“Electronic waste or e-waste describes discarded electrical or electronic devices. Used electronics which are destined for reuse, resale, salvage, recycling or disposal are also considered e-waste. Informal processing of electronic waste in developing countries may cause serious health and pollution problems, as these countries have limited regulatory oversight of e-waste processing.”

The e-waste recycling process is highly labor intensive and goes through several steps. Below is the step-by-step process of how e-waste is recycled,

- Picking Shed

When the e-waste items arrive at the recycling plants, the first step involves sorting all the items manually. Batteries are removed for quality check.

- Disassembly

After sorting by hand, the second step involves a serious labor intensive process of manual dismantling. The e-waste items are taken apart to retrieve all the parts and then categorized into core materials and components. The dismantled items are then separated into various categories into parts that can be re-used or still continue the recycling processes.

- First size reduction process

Here, items that cannot be dismantled efficiently are shredded together with the other dismantled parts to pieces less than 2 inches in diameter. It is done in preparation for further categorization of the finer e-waste pieces.

- Second size reduction process

The finer e-waste particles are then evenly spread out through an automated shaking process on a conveyor belt. The well spread out e-waste pieces are then broken down further. At this stage, any dust is extracted and discarded in a way that does not degrade the environmentally.

- Over-band Magnet

At this step, over-band magnet is used to remove all the magnetic materials including steel and iron from the e-waste debris.

- Non-metallic and metallic components separation.

The sixth step is the separation of metals and non-metallic components. Copper, aluminum, and brass are separated from the debris to only leave behind non-metallic materials. The metals are either sold as raw materials or re-used for fresh manufacture.

- Water Separation.

As the last step, plastic content is separated from glass by use of water. One separated, all the materials retrieved can then be resold as raw materials for re-use. The products sold include plastic, glass, copper, iron, steel, shredded circuit boards, and valuable metal mix.

E-cycle components re-use

1. Plastic. All the plastic materials retrieved are sent to recyclers who use them to manufacture items such as fence posts, plastic sleepers, plastic trays, vineyard stakes, and equipment holders or insulators among other plastic products.

2. Metal. Scrap metals materials retrieved are sent to recyclers to manufacture new steel and other metallic materials.